Automated Culvert Surveying & Inspection (ACSI) Systems

Published Aug. 9, 2023

Culverts and other flood control structures across the United States are in dire need of improved inspection methods. Currently, the inspection of the over 100,000 miles of levees and associated culverts is performed manually. This manual approach is impractical, costly, and inefficient given the vast scale and continual degradation of these critical structures. Automated Culvert Surveying & Inspection (ACSI) systems provide a 21st century solution that leverages advanced AI and computer vision software to revolutionize the way culvert inspections are performed. These systems offer numerous benefits over traditional manual inspection methods, including:

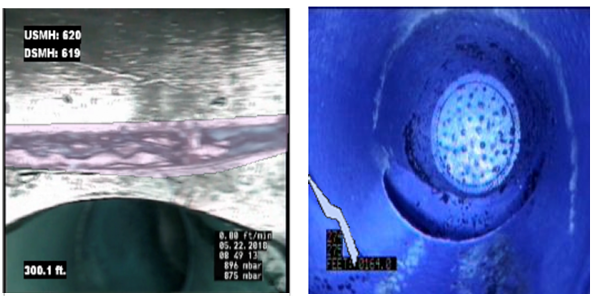

- A new tool for early detection and prevention of culvert failures: ACSI systems can rapidly gather imagery and sensor data to detect deficiencies and structural issues in culverts. The machine learning (ML) algorithms powering ACSI are trained to identify common problems like shape deformation, cracks, leaks, holes, joint failures, interior debris accumulation, and more. Figure 1 provides examples of culvert video segments that have been automatically labeled with deficiency tags by the ML models. The AI assessment enables issues to be identified early before they escalate into major failures. Automated analysis also allows more frequent and cost-effective inspections compared to manual methods. This leads to improved monitoring of the health and integrity of culverts, especially prior to and during flood events when the risk is highest

- AI-powered system augments inspector capabilities: By leveraging ACSI systems, inspectors can cover far more ground and inspect substantially more culverts in each time period. This increased efficiency frees up human resources to focus on the more complex decision making and repairs, rather than basic inspection duties. Rather than replace inspectors, ACSI augments and supplements their capabilities. The AI-powered systems can take over the routine inspections, while inspectors concentrate on oversight, quality control, and addressing the culvert issues discovered by the automation.

- AI-powered system reduces risk of injuries: In addition to efficiency gains, ACSI systems significantly improve inspector safety. Removing humans from direct contact with hazardous or hard to reach culverts reduces the risk of injuries. The robotic ACSI systems can be operated remotely from safe distances. This also enables inspection of cramped or submerged culverts that may be inaccessible to humans.

- AI-powered system delivers more accurate and consistent inspection data: The computer vision and machine learning capabilities of ACSI deliver more accurate and consistent inspection data compared to manual techniques. The AI algorithms are trained to identify defects and conditions using millions of sample images and defect scenarios. This level of training is impossible to replicate with human inspectors. The improved accuracy of ACSI allows infrastructure managers to make data-driven maintenance decisions based on precise condition assessments.

- AI-powered system extends service life of culverts at lower costs: By enabling better planning and prioritization of repairs, the ACSI approach can ultimately extend the service life of aging culverts at lower costs. The technology provides actionable information to target maintenance where it is needed most. The long-term cost savings of optimized repairs more than offset the initial investment in ACSI technologies.

In summary, Automated Culvert Surveying & Inspection delivers transformative capabilities not possible with legacy manual methods. The ability to rapidly survey vast networks of flood control structures using AI software keeps inspectors safe, efficient, and accurate. ACSI is a strategic innovation that provides deeper insight into infrastructure health while supporting proactive maintenance for the flood control systems critical to public safety.